Managing Corn for Silage

Corn silage is one of the top forages for livestock because it is a high-energy, palatable, and consistent feed source with high yields. Managing corn silage the same way as corn for grain will still produce acceptable silage, but several management changes can maximize both tonnage per acre as well as silage quality.

Hybrid Selection

Hybrid selection is important regardless of what the corn end use will be. To maximize either grain or silage yield, select high-yielding hybrids. Approximately half of corn silage yield comes from the grain. The grain fraction is high in energy and highly digestible (80-98%). This means selecting hybrids with high grain yields often yield more silage per acre that is also higher in quality.

The other half of silage yield comes from stover components (leaves, stalks, and cobs). These fibrous components are typically between 40-70% digestible. The digestibility of the stover will vary by hybrid, cutting height, moisture, and crop maturity at harvest. Hybrids with more leaves compared to stalks, for instance, will have higher stover quality.

- Select high-yielding hybrids with good agronomics and standability. Use forage quality data to select hybrids that provide high tonnage, milk per ton, and milk per acre.

- If silage data isn’t available, select hybrids that have high grain yields. Hybrids that yield more grain also tend to produce higher quality silage.

- Select hybrids that are 5-10 relative maturity units longer than normal.

- Longer-season hybrids typically have higher grain yields (~ 2 bu/ac more per unit increase in corn relative maturity). Longer-season hybrids also tend to have more stover.

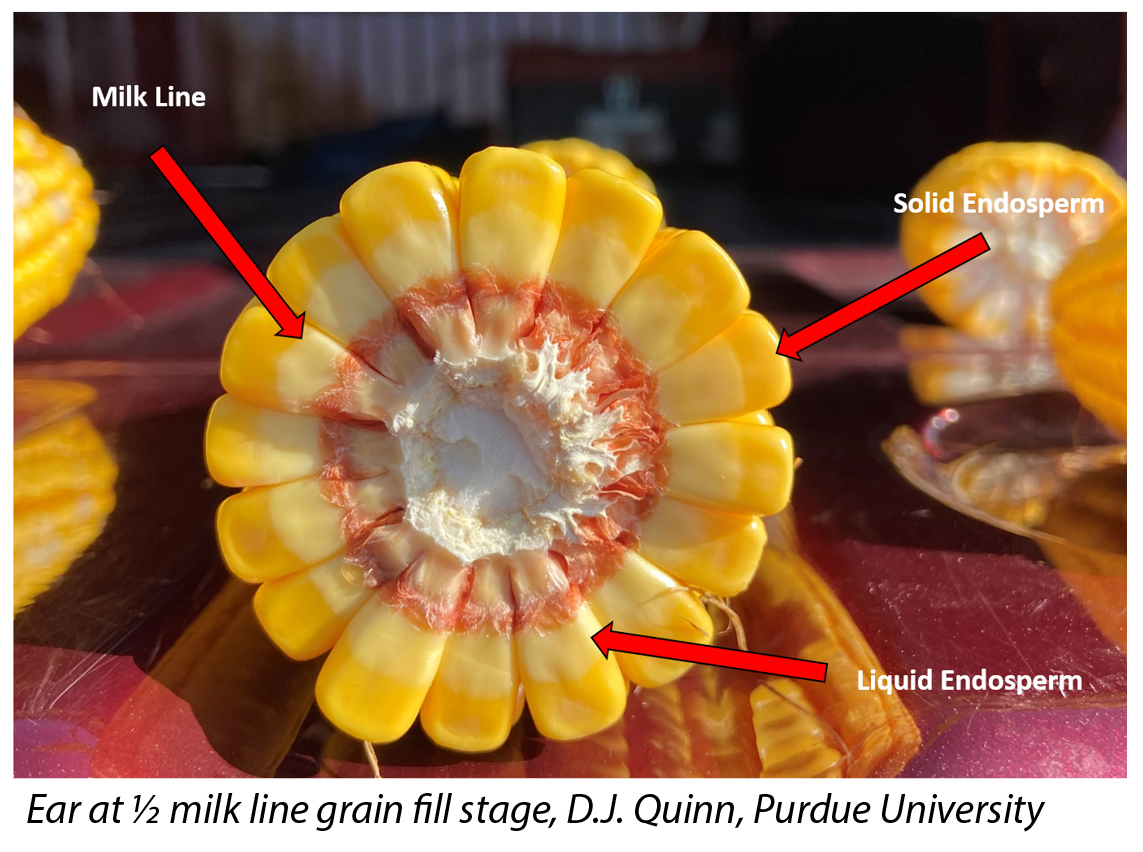

- Corn silage should be chopped around 1/2 milk line to improve fermentation and overall silage digestibility. Longer-season hybrids can provide a later harvest window. When chopping many acres or when relying on a custom chopper, consider logistics and timing when making hybrid selections.

- Select hybrids with corn rootworm traits if needed. Corn rootworm feeding will significantly reduce corn silage yields as well as silage quality if not managed.

- Monitoring corn rootworm pressure with sticky traps is a cheap and effective way to know the likelihood of pressure the following year.

- Fields of continuous corn have a much higher risk of damage due to corn rootworm.

- The latest results of silage testing for Wyffels corn products can be found on Wyffels.com

Planting and seeding rate

Maximum grain and silage yields typically occur when planted in early spring into suitable field conditions. Since many silage fields also have manure applied, minimize traffic and compaction issues associated with manure equipment by staying off fields when conditions are too wet. Planting into good field conditions is more important in maximizing yield than planting early.

- Plant a slightly higher population than you do when planting corn for grain.

- Optimum seeding rates should be at least 1500 seeds per acre greater when planting corn silage. The added seed cost will be recouped by higher silage yields.

- Narrow rows have a larger advantage for silage yields than they do for grain yield.

- 20-inch rows will yield ~7% more silage compared to 30-inch rows.

Fertility Management

Optimum soil test levels do not differ when producing corn silage vs. corn for grain. The important factor to consider when producing corn silage is the fact that the whole plant is being harvested and removed from the field compared to just the grain, meaning nutrient removal rates are much higher. Over 25% more phosphorus and over 3 times as much potassium is removed per acre when corn is chopped for silage compared to when it is harvested for grain. Fertilizer application rates accounting for crop removal must be increased to make up for the lost nutrients.

Balanced fertilizer applications can lead to higher yields in grain production as well as forage production. Implementing nutrients like Sulfur, Boron, Zinc and Manganese can lead to a larger heavier ear as well as a greener healthier plant with more vegetative growth.

- It is important to maintain the lower corn leaves when harvesting corn for silage since the leaves add to total tonnage while also providing higher quality fiber. Slightly higher nitrogen rates may increase the likelihood that lower leaves are maintained, especially in fields without significant manure history. Using nitrogen rates on the higher end of the recommended range for your area is a good place to start.

Disease Management

Corn diseases are important in silage production because they not only can introduce mycotoxins into the feed, but they can also decrease yield and detract from the nutritive quality of the silage. Leaf diseases can reduce yield and decrease silage quality. Research in Illinois has shown that corn treated with a fungicide not only reduces corn diseases, but it also decreases Neutral Detergent Fiber (NDF) and increases the NDF digestibility. Fungicide-treated corn has been shown to have improved fermentation as well.

- Pay attention to preharvest intervals (PHI) when selecting fungicides to use in corn silage production, especially in situations where more than one application may be necessary.

- Fungicides applied at R1 will help decrease ear rots that produce mycotoxins, like Gibberella, which produce DON, or vomitoxin.

- Fungicides containing a triazole tend to be better at reducing DON content.

Harvest

Proper silage harvest timing and techniques along with proper storage conditions are just as important as in-field management of corn for silage. Improper harvest timing and poor storage conditions can easily cause 25% losses in both dry matter and silage quality.

- Harvest when whole plant moisture is 65-70% and the crop is at 1/2 to 2/3 milk line.

- Chopping before kernels get overly mature helps them break into smaller pieces during chopping and processing, improving the efficiency of fermentation and improving digestibility.

- Hybrid selection and the relative maturity of hybrids can be used to help widen the harvest window if needed.

- If silage is at 1/2 milk line but still >70% whole plant moisture, increase the cutting height slightly to reduce the silage moisture content. The wettest part of the plant is the stalk, which is also the poorest quality. By increasing cutting height, the moisture will be reduced.